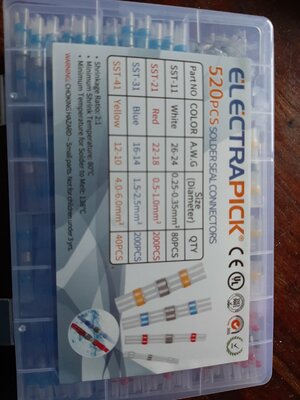

so.. fed up with soldering under the dash and then realising i haven't put the heatshrink wrap on the cable so i thought id try these..

brought them on the company credit card as didn't think they'd be that great...i was wrong.

they are basically high temp heat shrink with 2 rings of glue and low temp solder in them ..

the solder melts at they say around 135c altho they worked better at 180c

what i love about them is they are waterproof , the rings are the glue and seal the cable ,i cant pull em apart.

i used a small gas powered heat gun which did the job great..

quite impressed with em to be honest...

cant mark em down. ,brilliant.

their available on amazon and ebay in various quantity boxes.

altho i got the gas torch from amazon.

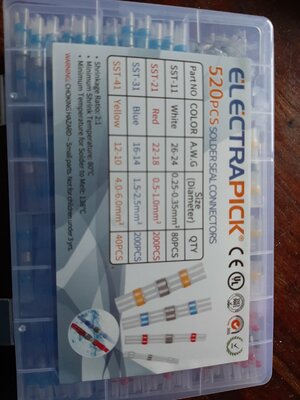

brought them on the company credit card as didn't think they'd be that great...i was wrong.

they are basically high temp heat shrink with 2 rings of glue and low temp solder in them ..

the solder melts at they say around 135c altho they worked better at 180c

what i love about them is they are waterproof , the rings are the glue and seal the cable ,i cant pull em apart.

i used a small gas powered heat gun which did the job great..

quite impressed with em to be honest...

cant mark em down. ,brilliant.

their available on amazon and ebay in various quantity boxes.

altho i got the gas torch from amazon.