I was thinking of posting this in the zetec section, but hopefully, there will be loads of piccies, and even a few "HOW-TO's" coming out of this.

As some of you are aware, my pride and joy has suffered lately,not to mention the humiliation at a certain track event this year .

.

Everything is in place for the re-birth, so i made a start today.

Parts to be replaced onto the replacement engine/gearbox:

Gates cambelt kit.

New water pump.

Rear crankshaft oil seal.

New clutch kit, pressure plate and friction plate, slave cyl.

As my engine has a recent new sump pan, i will also be swapping that.

I started by getting at the cambelt and water pump. The belt and pulleys, although not looking in really bad condition will be replaced anyway, better do it now, I have a datum point for any future possible replacement.

Water pump:

Just three bolts to get the pulley off, then four bolts to get the pump body off the block. I found it also to be in pretty good nick, this pump has the plastic impeller, the new replacement has the metal impeller.

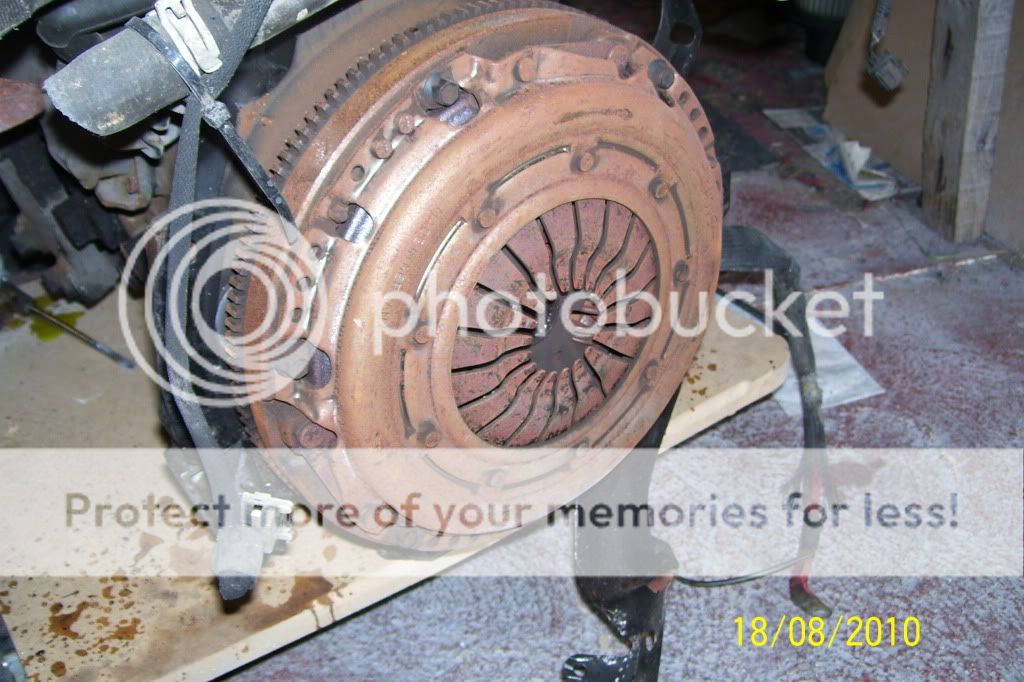

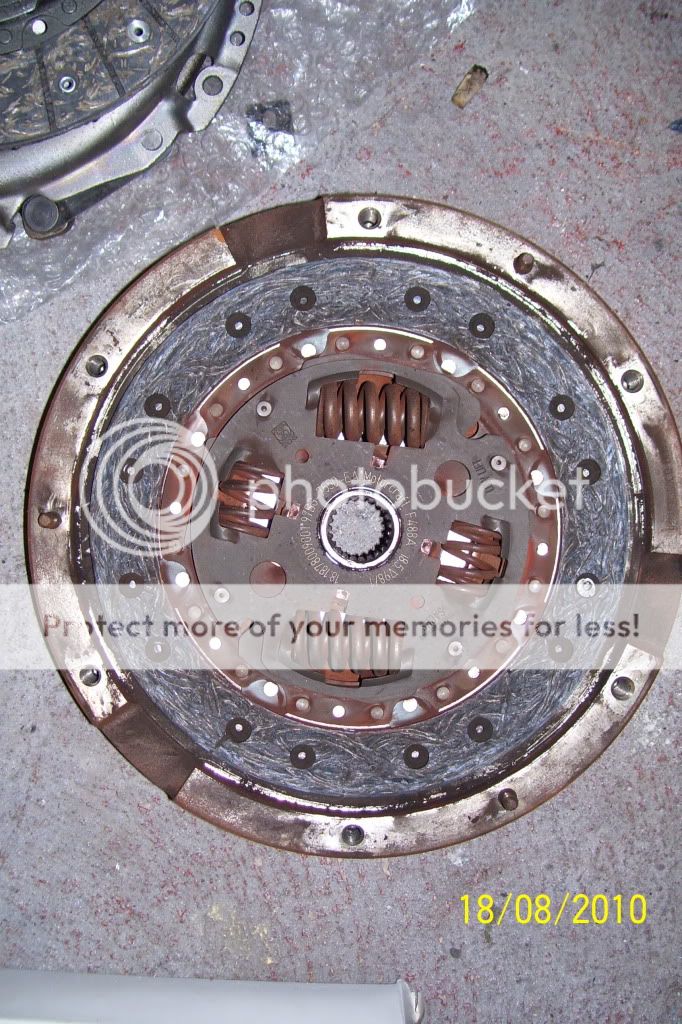

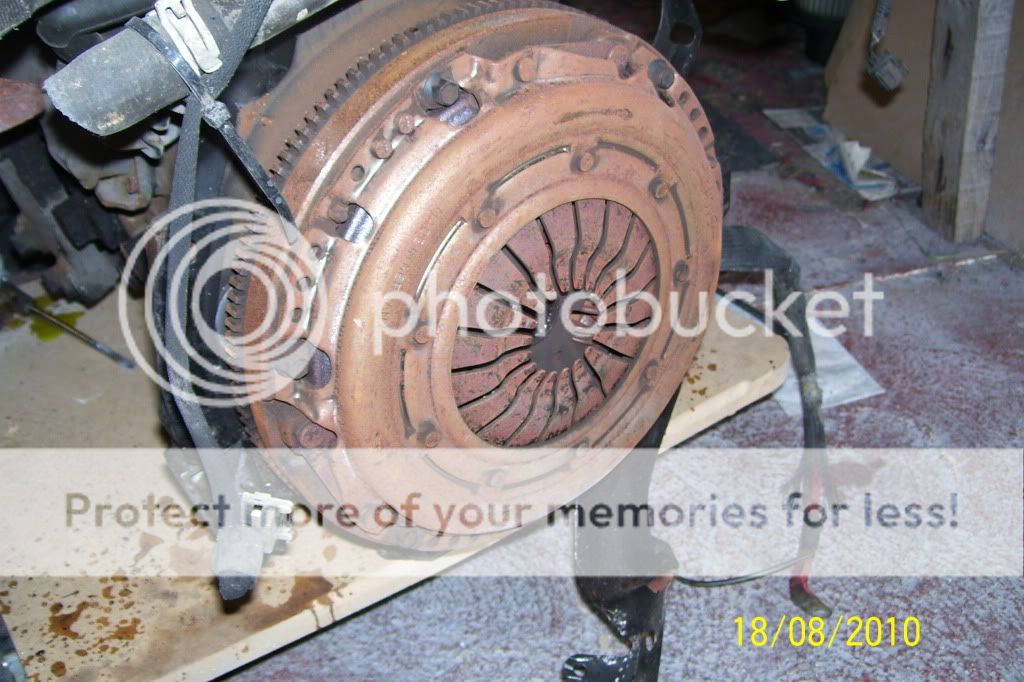

Clutch:

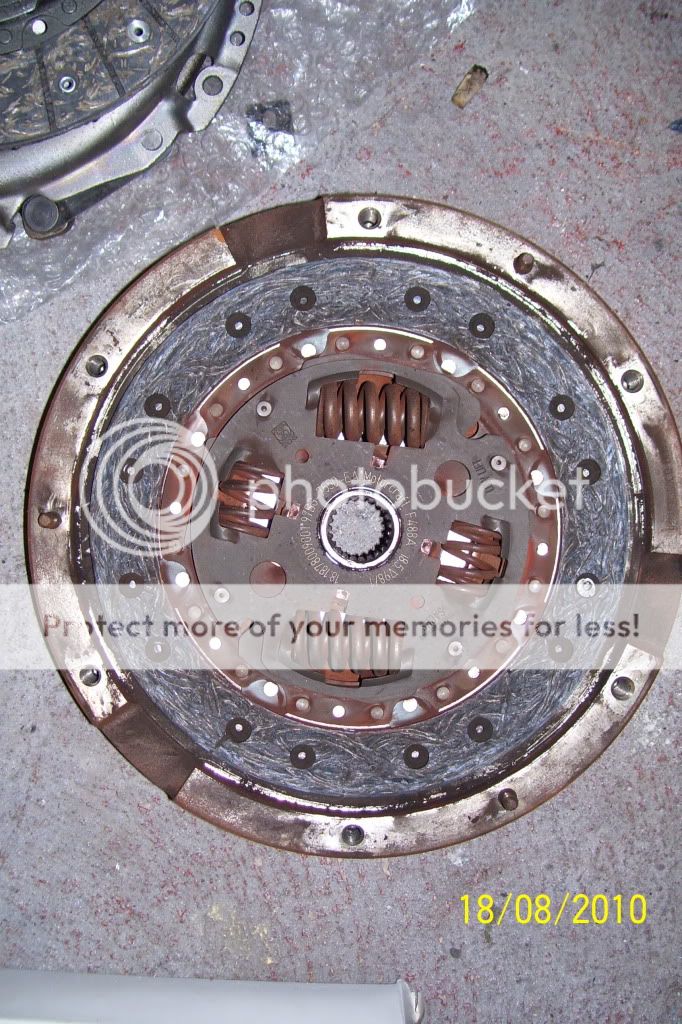

The clutch was ready for the bin, just starting to slip i'd imagine, as a couple of the rivets were nice and shiney. The replacement clutch kit got me scratching my head a bit. The one I removed is appx 230mm in diameter, the new one is appx 240mm although after checking it, it all fits perfectly ok but the 240mm one does fill the flywheel recess, whereas the smaller one looks lost in there. Did this engine have a small clutch fitted to it, and what difference will it make fitting the larger one?

Ok, the piccies:

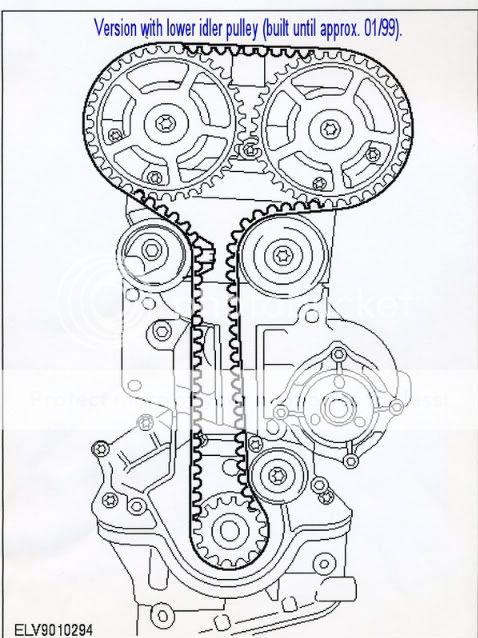

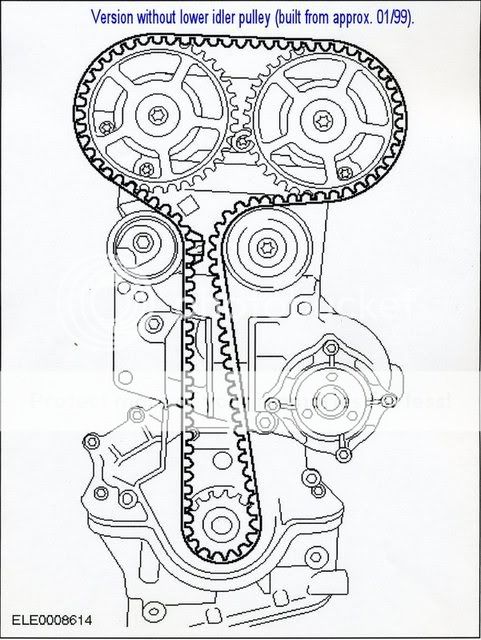

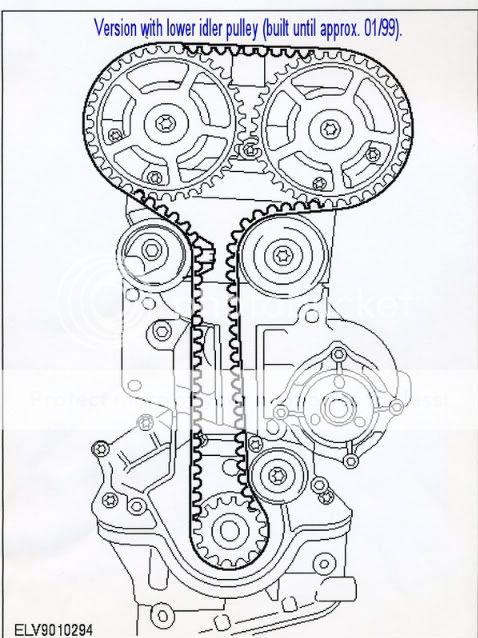

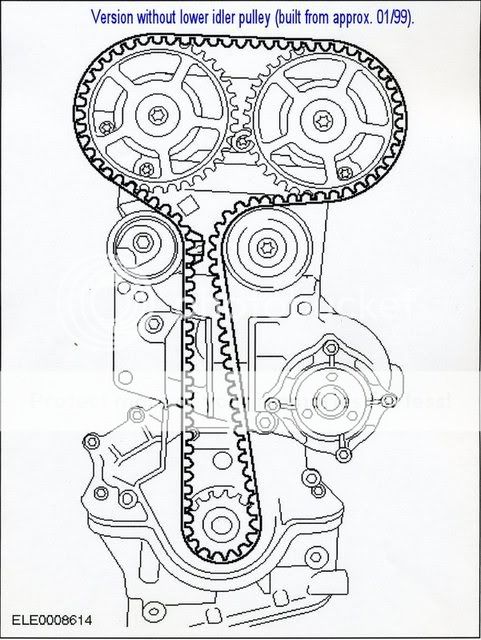

Timing covers removed to show belt and pulleys, also, water pump removed. All looks nice and clean inside the water pump housing.

.

You can see from this that although the engine came from a "99" T reg car, the belt setup is for the earlier type ie "98" engine, backed up by the fact that the engine block has "98" stampeed into its block and head.

.

Water pump removed, showing plastic impeller:

and the new one with metal impeller:

.

Now the clutch and parts.

Compare:

Here she is:

and off, the difference between the old and the new is pretty obvious, shiney rivets, especially at the appx 3.00oclock position:

.

.

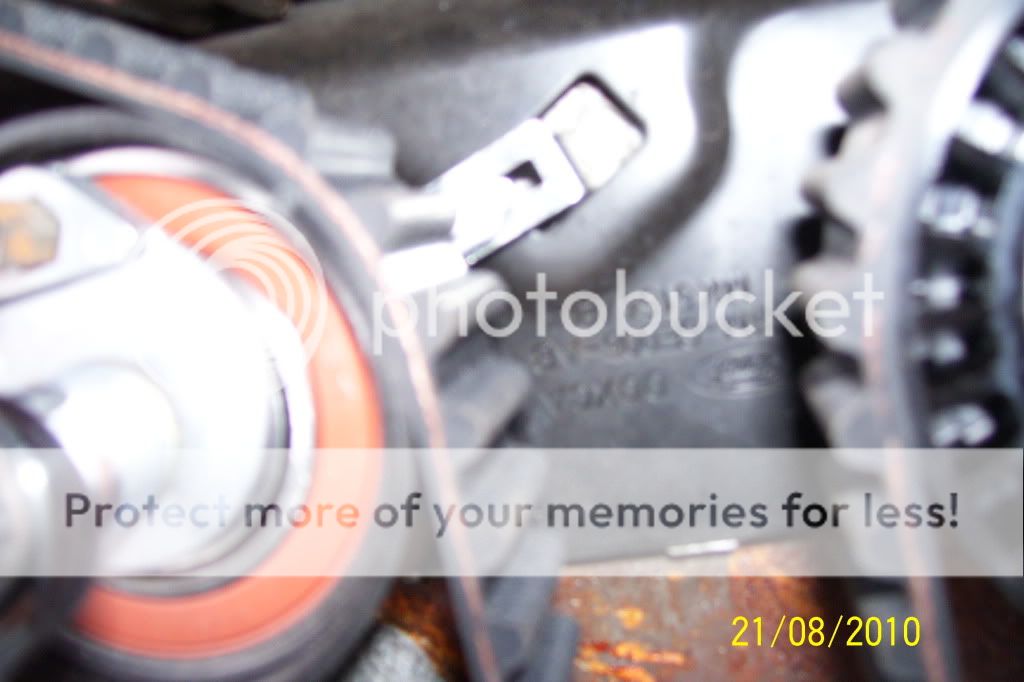

...and the slave cyl from the gearbox bellhousing, old and new, the old one is just beginning to show slight leakage:

.

.Some engine flushing tomorrow and general degreasing of the gearbox bell housing and engine block.

DAY TWO:

Not much to report today, took the oil seperater off to clean it and take a peek into the crankshaft..........oooohhhhh spooky. Flushed out the engine, and did a bit of degreasing. Hopefully the cambelt kit and cranckshaft oil seal will be in tomorrow.

.

.

DAY 3:

Waited all day for the cambelt kit to arrive, it came at 6.30pm, by which time i had cleaned up, so that'll get done tomorrow (Saturday) I did manage to replace the water pump, and the rear crankshaft oil seal.

Out comes the old water pump, looks in pretty good nick, and feels ok, but, it's an unknown quantity, much easier to change while the engine is on the floor.

.

The old plastic impellered pump on the left, the new metal impeller pump on the right, complete with new "O" ring seal.

.

New "O" ring in place, ready to fit:

.

Remember to clean out the recess for the seal to seat properly:

Then the camera went dead, recharge for tomorrow.

DAY 4:

All done today barring a few bits that can wait. The engine is ready to bolt onto the gearbox.

1) Crankshaft rear oil seal replaced.

2) Flywheel replaced.

3) Clutch assembly replaced.

4) Cambelt and pulleys replaced.

Piccies etc:

Out comes the old oil seal....................

....and in with the new.

Flywheel cleaned up, aligned and bolted up to the correct torqu 112nM, threadlocked:

These air tools are brill..

Finally tightened, notice the "lock" on the flywheel to hold it against the torqu wrench.

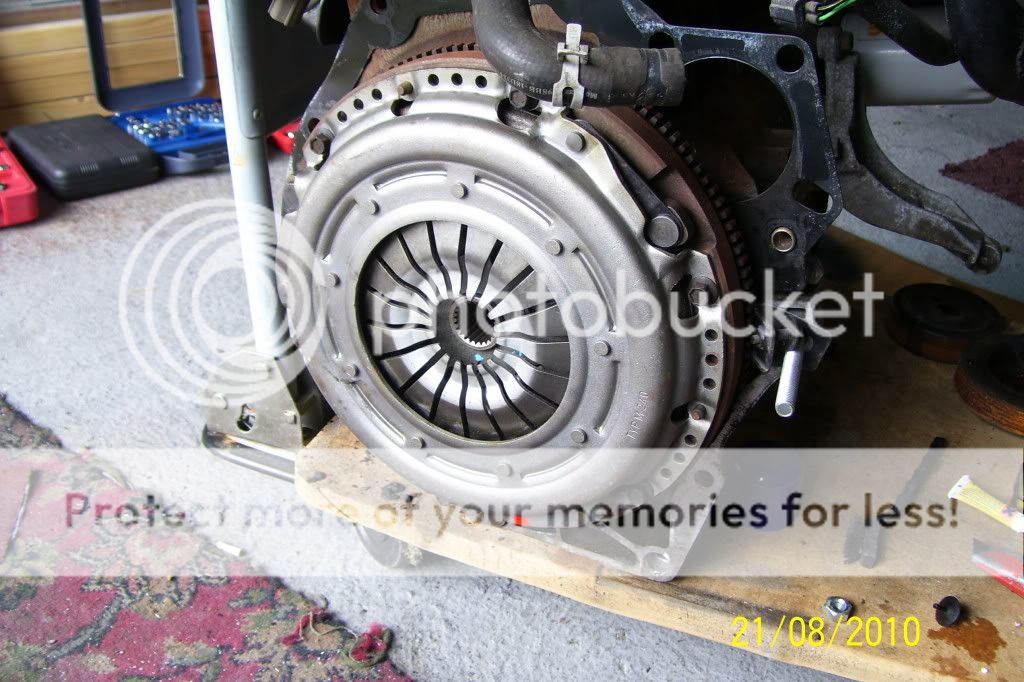

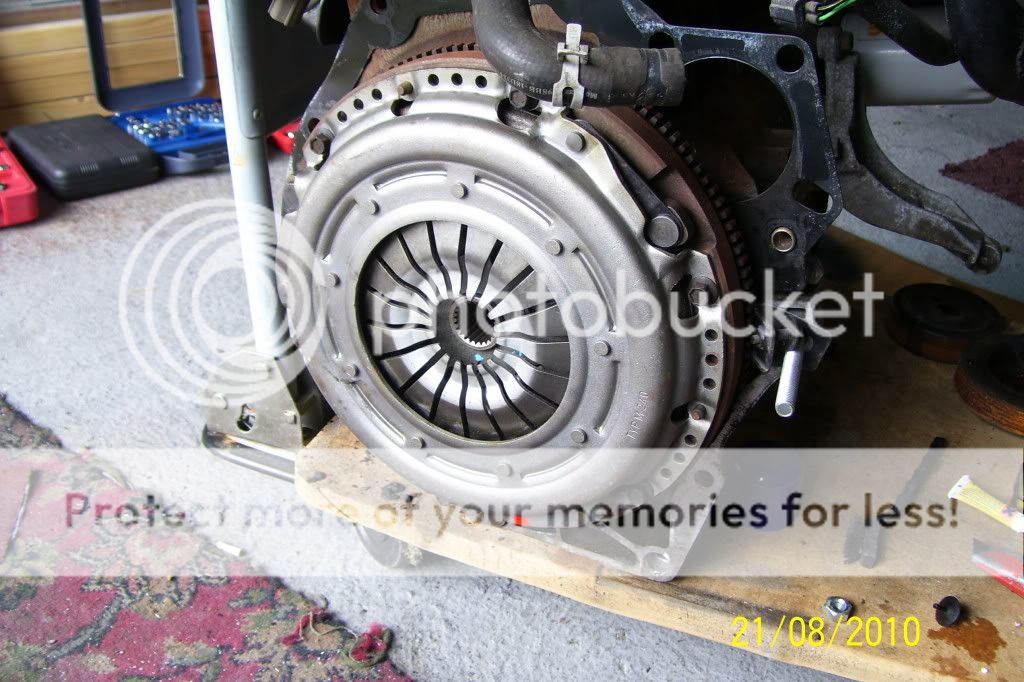

Next goes the new clutch.

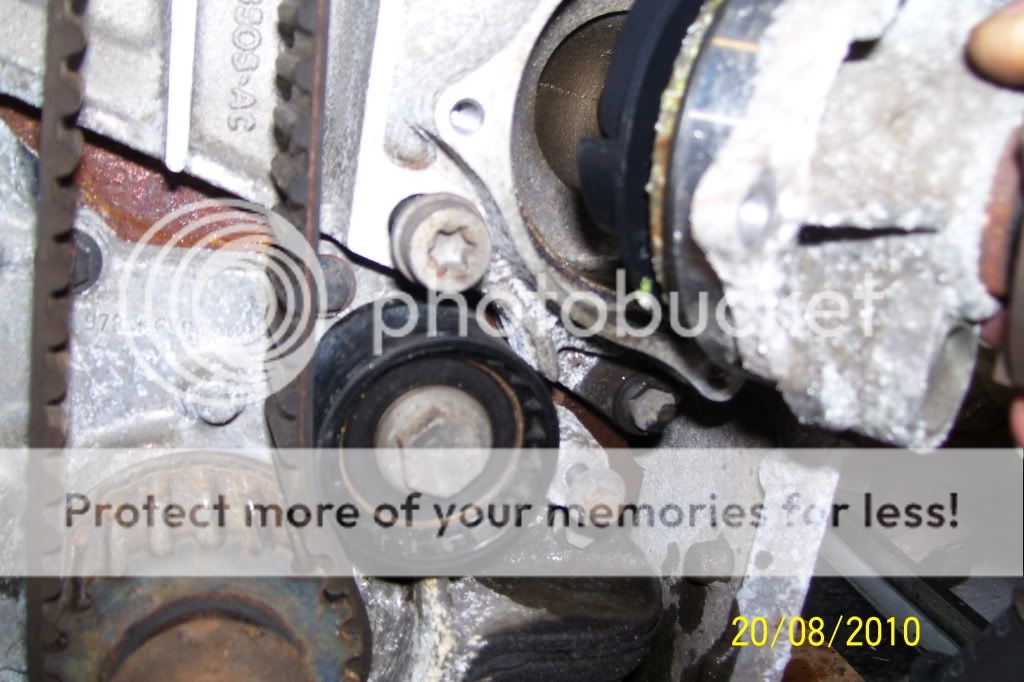

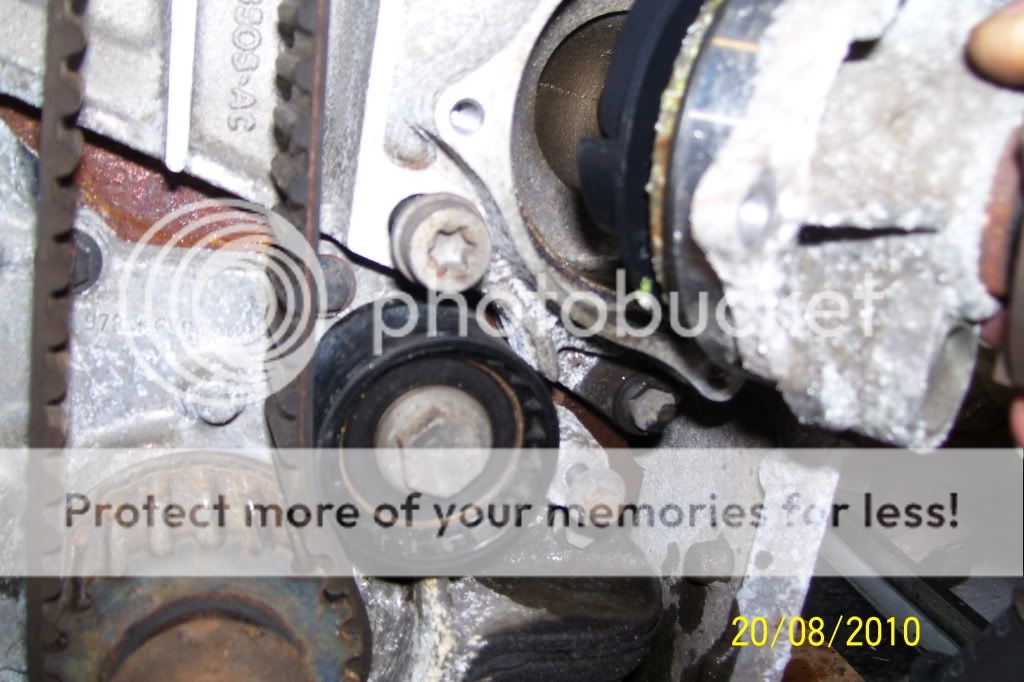

Cambelt and new pulleys:

I went for the "Gates" brand

First job is to get the engine turned to TDC at No1 cylinder, then lock off the camshafts:

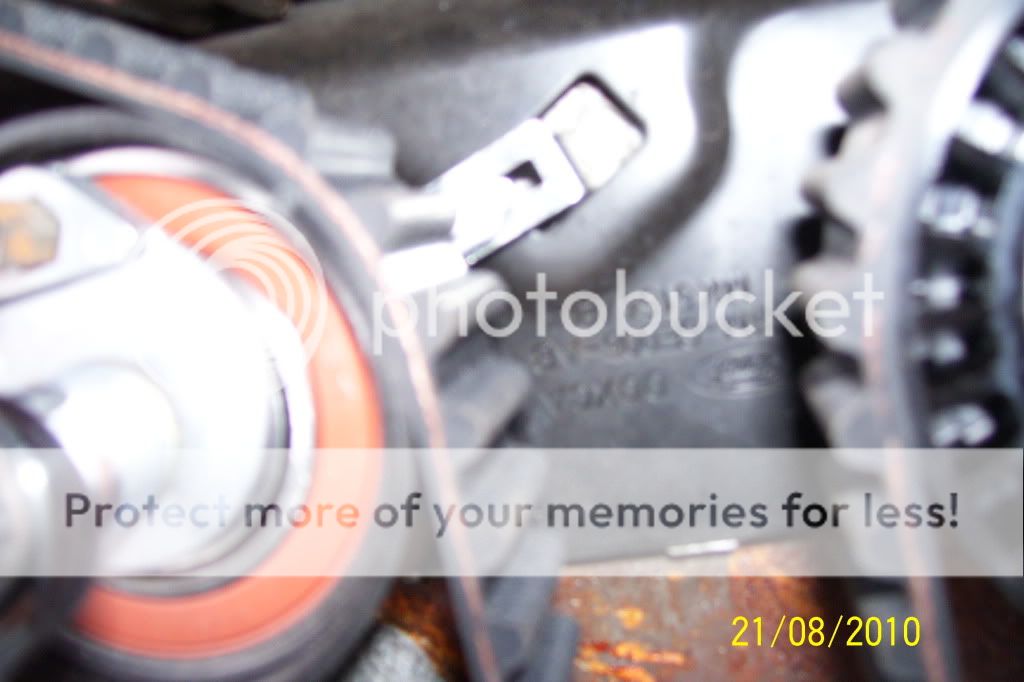

Lock the crank shaft with the locking peg:

Remove the old belt and pulleys, which to be fair were looking in pretty good nick, although i have no record of a new belt kit ever been fitted.

Notice new water pump fitted.

On with the new kit, and adjust the tensioner to align the pointer.

Back on with the covers, temporarily, as the middle (engine mount) will need to come off again before final transplant, reasons for this later :angel:

All camshaft and cranckshaft locks removed, i decided to check the IACV (idle air valve) under the inlet manifold. This is another one of those fiddly jobs made easier while the engine is on the floor. I have no idea what it ran like, but all seems ok!, so it went straight back on after a minor clean.

As some of you are aware, my pride and joy has suffered lately,not to mention the humiliation at a certain track event this year

Everything is in place for the re-birth, so i made a start today.

Parts to be replaced onto the replacement engine/gearbox:

Gates cambelt kit.

New water pump.

Rear crankshaft oil seal.

New clutch kit, pressure plate and friction plate, slave cyl.

As my engine has a recent new sump pan, i will also be swapping that.

I started by getting at the cambelt and water pump. The belt and pulleys, although not looking in really bad condition will be replaced anyway, better do it now, I have a datum point for any future possible replacement.

Water pump:

Just three bolts to get the pulley off, then four bolts to get the pump body off the block. I found it also to be in pretty good nick, this pump has the plastic impeller, the new replacement has the metal impeller.

Clutch:

The clutch was ready for the bin, just starting to slip i'd imagine, as a couple of the rivets were nice and shiney. The replacement clutch kit got me scratching my head a bit. The one I removed is appx 230mm in diameter, the new one is appx 240mm although after checking it, it all fits perfectly ok but the 240mm one does fill the flywheel recess, whereas the smaller one looks lost in there. Did this engine have a small clutch fitted to it, and what difference will it make fitting the larger one?

Ok, the piccies:

Timing covers removed to show belt and pulleys, also, water pump removed. All looks nice and clean inside the water pump housing.

.

You can see from this that although the engine came from a "99" T reg car, the belt setup is for the earlier type ie "98" engine, backed up by the fact that the engine block has "98" stampeed into its block and head.

.

Water pump removed, showing plastic impeller:

and the new one with metal impeller:

.

Now the clutch and parts.

Compare:

Here she is:

and off, the difference between the old and the new is pretty obvious, shiney rivets, especially at the appx 3.00oclock position:

...and the slave cyl from the gearbox bellhousing, old and new, the old one is just beginning to show slight leakage:

.

.Some engine flushing tomorrow and general degreasing of the gearbox bell housing and engine block.

DAY TWO:

Not much to report today, took the oil seperater off to clean it and take a peek into the crankshaft..........oooohhhhh spooky. Flushed out the engine, and did a bit of degreasing. Hopefully the cambelt kit and cranckshaft oil seal will be in tomorrow.

.

.

DAY 3:

Waited all day for the cambelt kit to arrive, it came at 6.30pm, by which time i had cleaned up, so that'll get done tomorrow (Saturday) I did manage to replace the water pump, and the rear crankshaft oil seal.

Out comes the old water pump, looks in pretty good nick, and feels ok, but, it's an unknown quantity, much easier to change while the engine is on the floor.

.

The old plastic impellered pump on the left, the new metal impeller pump on the right, complete with new "O" ring seal.

.

New "O" ring in place, ready to fit:

.

Remember to clean out the recess for the seal to seat properly:

Then the camera went dead, recharge for tomorrow.

DAY 4:

All done today barring a few bits that can wait. The engine is ready to bolt onto the gearbox.

1) Crankshaft rear oil seal replaced.

2) Flywheel replaced.

3) Clutch assembly replaced.

4) Cambelt and pulleys replaced.

Piccies etc:

Out comes the old oil seal....................

....and in with the new.

Flywheel cleaned up, aligned and bolted up to the correct torqu 112nM, threadlocked:

These air tools are brill..

Finally tightened, notice the "lock" on the flywheel to hold it against the torqu wrench.

Next goes the new clutch.

Cambelt and new pulleys:

I went for the "Gates" brand

First job is to get the engine turned to TDC at No1 cylinder, then lock off the camshafts:

Lock the crank shaft with the locking peg:

Remove the old belt and pulleys, which to be fair were looking in pretty good nick, although i have no record of a new belt kit ever been fitted.

Notice new water pump fitted.

On with the new kit, and adjust the tensioner to align the pointer.

Back on with the covers, temporarily, as the middle (engine mount) will need to come off again before final transplant, reasons for this later :angel:

All camshaft and cranckshaft locks removed, i decided to check the IACV (idle air valve) under the inlet manifold. This is another one of those fiddly jobs made easier while the engine is on the floor. I have no idea what it ran like, but all seems ok!, so it went straight back on after a minor clean.

Last edited: