Only just noticed this Noel, glad they arrived ok, let us know how you get on with them...

- - - Updated - - -

- - - Updated - - -

Started the mot repair work today on my Ebony C1 (I need a name for the old girl...) she has been stood for a few months due to various personal issue's, but hopefully now I can get back on track and get her tested and looking her best again, then it's on to sort out my recent C2 purchase from Mike.

Anyway here's some piccies from today's jobs...

Got her up on axle stands and wheels off to have a good look around.

View attachment 13293

Here's a "not pretty" picture... big hole at the front passenger side sill...

View attachment 13294

View attachment 13294

from a different angle...

View attachment 13295

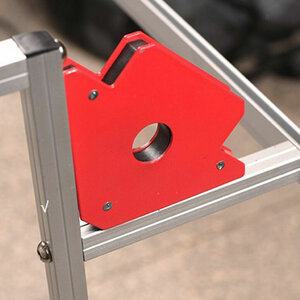

And we all know what this is, don't we.....found this in the rear end passenger side, safe to say it has now been well and truly discarded.. expecting the same on the other side, but there's enough here for now to keep me busy for a while...

View attachment 13296

your doing great work my friend keeping her going when by the looks of it anybody else probally would have sent her to the race track in the sky

your doing great work my friend keeping her going when by the looks of it anybody else probally would have sent her to the race track in the sky